Blasting Equipment

Surface Coating

Grounting Machines

IBIX Systems

BLASTING EQUIPMENT

SANDBLASTERS

Blasting equipment NANO 3

The aero-abrasive cleaning system NANO IBIX 3 is a special kit for samples, ideal also for small cleaning treatments and spot blasting

It is equipped with a 3 liters tank that can be fully emptied, making the change of abrasive easier and avoiding the risk of mixing different blasting materials; this is possible because of a special plastic funnel installed inside the tank of the IBIX machine

The kit NANO IBIX 3 is available in three versions:

KIT NANO IBIX® 3

Kit equipped with a 3 liters tank that can be fully emptied, making the change of abrasive easier and avoiding the risk of mixing different blasting materials; this is possible because of a special plastic funnel installed inside the tank of the IBIX machine; the kit is available with a suitcase of abrasives for samples.

NANO Plus

It is a double functioning (dry/wet) aero-abrasive device, equipped with a special “quick connect” system and two easily interchangeable pistols, a standard H2O and an Helix.

NANO IBIX® 3 con penna

The Nano Ibix reveals its top effectiveness with the microtip Ibix; this tool allows the operator to work on the smallest details with the maximum comfort; it is made of tungsten carbide, a very resistant and durable material compared to ceramic tips.

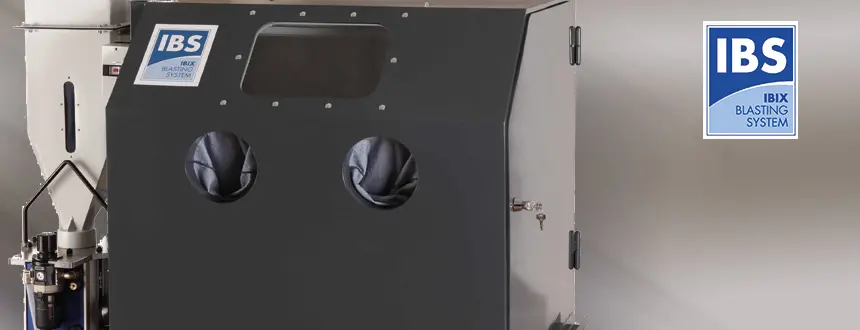

BLASTING CABINETS

Blasting Cabinets IBS 100

One machine, 2 working tools

IBS is the innovative pressure blasting/ shot-peening cabinet combined with an eco-blaster. The eco-blaster can be easily disconnected and used separately on large installed items that cannot be moved or removed.

- VERSATILE

It can be used in closed rooms or given several other cleaning situations- working with pieces larger than the effective working area or at a client’s premises with pieces that cannot be removed or are hard to handle. - ENVIRONMENTALLY FRIENDLY

100% sealed enclosures do not create pollution or health hazards. - POWERFUL AND EFFICIENT

High performance, increased yield and productivity for works requiring pressure. - EASE OF OPERATION – TOTAL VISIBILITY

Dust and waste resulting from cleaning are sucked by a high power pump, which guarantees ease of operation and total visibility. - LOW OPERATING COSTS

The selective recovery of blasting and inert materials markedly cuts down costs and material consumption. - RECOMMENDED BLASTING MATERIALS:

Use blasting materials recommended by IBIX only to ensure proper functioning of IBS equipment.

ELECTRO-COMPRESSOR

Electro-compressor E90

An electric air compressor with belt drive, E90 is equipped with a pressure switch with protection against overloading in order to guarantee maximum safety and a breaker valve which allows continuous operation. The large dimension wheels make E90 practical and easy to handle.

- Wheeled electrical air compressor

- Power Supply: (Volt/Hz): 400/50

- Noise level: (db): 77

- Air flow rate: (Lt/min – m3/h): 830 – 50

- Max. pressure: (bar – psi): 10 -145

- Dimensions: (LxPxH cm): 58x75x79

- Weight: (Kg): 135

MOTOR-DRIVEN COMPRESSORS

Motor-driven compressors IB2 Trolley

The technological solution that guarantees low environmental impact, noise reduction and low emissions.

TECHNICAL FEATURES

- Air compressor with screw – type compression unit –

- wheeled for maximum versatility and compactness

- Electric motor: 2.2 kW / 230 V

- Air flow rate: 300 l/min (10.59 CFM)

- Max. pressure: 10 bar (150 psi)

- Noise level: 69 dB(A)

- Weight: 55 kg (121 lb)

- Dimensions: 700x650x700 mm (27x25x27 in)

A design that lets you guess what this compressor contains: dynamism, energy efficiency, ease of use, and ecological operation. IB2 Trolley is the smallest existing screw compressor on the market, capable of delivering 450 LT / M (0.45 M3 / 1).

Equipped with 4-stroke Honda petrol engines, with air cooling and tear-off start it succeeds with a 1/1 direct coupling to ensure 24-hour use.

INERT MATERIALS

IBIX® ART

IBIX®ART is an air-abrasion specific blasting material selected by IBIX to be used with IBIX® eco-blasters and Micro-air-abrasion IBIX® and HELIX® equipment.

Natural, 100% eco-friendly mineral, for a wide range of applications in sandblasting, micro-blasting, dry and humid air-abrasion thanks to the many granulometry curves available.

Cost-saving:

Tiny crystal composition, high relative density, the lowest blasting pressure- all this to minimise blasting material consumption, reduced by 50-75% in comparison with traditional abrasives used in blasting.

High productivity:

As small amounts of aggregate are used (2 – 5 kg/m²) and productivity is high (10 m²/h), using IBIX®ART helps to significantly reduce blasting and cleaning costs.

In fact, IBIX®ART, the inert material for air-abrasion, features a high cutting speed due to the high number of aggregate grains per volume hitting the surface (144/units of volume against 85 for slug).

Depending on the operating conditions, this means higher blasting speed (m2/h) up to 50-100%, plus a very low abrasive consumption (-66%). So, productivity is enhanced when compared with traditional slug-based abrasives or made from stones and glass.

* These are indicative values only. They should be regarded as average values only.

Clean:

IBIX®ART is a chemically neutral, non-metal inert material. Free of toxic chemicals, IBIX®ART does not emit free silica and it is not carcinogenic. It is 100% eco-friendly and in full compliance with safety at work regulations and environmental standards. Does not contain ferrite, impurities or pollutants; it is not radioactive and is free of salts. All these characteristics combined with low consumption result in a significant reduction of disposal costs.

Safe:

IBIX®ART inert material for air-abrasion is not toxic and therefore, it is well below the allowed maximum values set forth by the environmental protection standards on silicogenic (crystalline silicon), toxic and carcinogenic components. A safe and clean work environment is so assured; noise is markedly reduced thanks to a low-pressure blasting method.

Truly hard. No dust produced:

IBIX®ART inert material for air-abrasion features high hardness (7.5 – 8 Mohs) and toughness, very low friability and high relative density (4.1). All these characteristics plus a sub-angular morphology facilitate a dust-free dry blasting process. Top quality blasting- by adjusting the grain size used and the operating pressure you can perfectly control the work to obtain a perfectly uniform surface roughness. The SA3·blasting standard is easily met.

IBIX®ART’s high relative density helps transfer a lot of kinetic energy when the blasting material hits a surface, which translates into a marked increase in efficacy and in blasting and cleaning performance.

Due to the high toughness and low friability showed by IBIX®ART, it can be reused several times, thus cutting down blasting and cleaning costs in connection with consumables.

Non-hygroscopic:

IBIX®ART inert material for air-abrasion does not absorb moisture, and so storing and using the product are truly easy tasks.

IBIX®ART is the inert material specific for dry and humid air-abrasion selected to obtain the best performance of the IBIX® System.

ELECTRIC DRYERS

Electric Dryers AMD 6

Electric Air Drier T-DRY 6 for A 90 compressor

- Air drying capacity: 600 l/m

- Volt/Hz: 230/60/1

- Max. Watt: 260

- Weight: 23 kgs

Complete with hose and fittings for quick coupling to the A90 compressor or equivalent.

ACCESSORIES

Nozzle Boxes IBIX 9

The nozzles box extends the application possibilities of the IBIX models, providing the possibility of increasing or decreasing the area of operation, changing the pattern and using all the possible media grain sizes. The box is made up of cylindrical, selective nozzles which concentrate the jet of media for a decisive and precise cleaning and of Venturi nozzles which open the area of operation guaranteeing a delicate treatment. The nozzles are made of tungsten carbide, a resistant material that guarantees durability and strong resistance to abrasion.